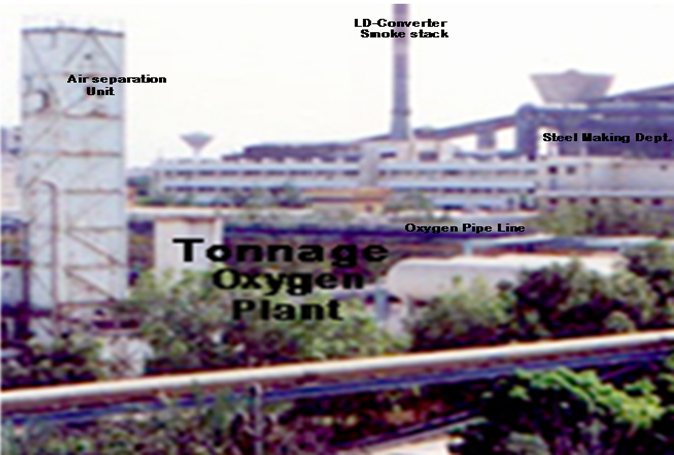

TONNAGE OXYGEN PLANT(Pak. Steel).

Since

the LD-Converter can not produce steel without Oxygen and for a LD-Converter

shop to become an economically tonnage steel producer, high purity oxygen

should be readily available in large quantities. So Oxygen generating plant

affiliated with LD-Converter(BOF) must have high degree of operating continuity

and reliability.

The

composition of dry air is approximately 78% nitrogen, 21% oxygen, and 1% argon (by volume) plus small amounts of carbon dioxide,

neon, helium, krypton, hydrogen, and xenon. In addition, variable amounts of

water vapors are present (depending upon humidity) plus other gases produced by

natural processes and human activities.

The portions of the air separation process

that operate at very low temperatures (the distillation columns, heat

exchangers and cold interconnecting piping sections) must be well insulated to

minimize energy consumption and avoid operating problems. To accomplish this,

these components are located inside insulated, sealed (and nitrogen purged) structures called "Cold boxes” or Air separating unit.

Appearance of cold boxes of Tonnage Oxygen

Plant.

In

process of O2 production, the air is compressed, cooled and much of the water vapors

and CO2 in the incoming air is condensed and removed. The

Nitrogen, Oxygen and Argon are produced

by the fractional distillation of liquid air in an air separation unit; a

process that separates liquid nitrogen which boils at 77.3 K, from argon which

boils at 87.3 K and liquid oxygen which boils at 90.2 K.

The distillation system uses two

distillation columns in series. Nitrogen leaves the top of each distillation

column; oxygen leaves from the bottom.

Argon has a boiling point similar to that of oxygen and is preferentially

stay with the oxygen product. As high purity oxygen is required, crude argon must be separated

&removed from the distillation system.

Pakistan

Steel has an Oxygen Plant, manufactured by L'Air Liquide of France.The

main consumer of oxygen is the Steel Making Department where oxygen is blown

into the LD-Converters to convert molten pig iron into raw steel. Oxygen is

also supplied to the Central Maintenance department and other departments where

it is used in welding and cutting processes.

The

booster compressors (02 air

compressors 42,500 nm3/hr each) pump the gaseous oxygen produced by the oxygen

plant into the storage receivers at high pressure.

LD-Converter

steelmaking is a cyclic process whereas

air separation is a continuous steady state production process. Oxygen

storage is necessary to match the continuous output of an air separation plant

with the cyclic demand for oxygen in steel making department.

Since

the cost of electricity is the largest operating cost incurred in air

separation plants as heavy electric motors are used to drive the compression

equipment and also power is required for process heaters, instrumentation

systems and cooling systems.

Therefore

the issue of cost effective amount of liquid oxygen storage required for smooth

raw steel production at Steel Making Department, is resolved by mutual exchange

of production information between Steel Making Department and Oxygen plant.

Oxygen is delivered through pipelines to the Steel Making Department.

The

production capacity of the Oxygen plant of Pakistan Steel is as under.

Oxygen

|

Nitrogen

|

|

Output

(cubic meters/hour):

|

15200

|

9000

|

Purity:

|

99.5%

|

15ppm

|

Pressure

(bar):

|

0.15

|

0.80

|

The

gaseous Nitrogen produced is mainly used as a shielding & purging gas at

Cold Rolling Mill in the annealing & galvanizing units. Nitrogen is also

used in the hydraulic systems of the Cold Rolling and Hot Strip Mills and as an

inert gas at the Coke Dry Quenching Plant. Nitrogen is also used at purging

unit of steel making department.

High

purity Argon is used in production of high quality steel grades ( e.g

automotive grades).So provision of high purity Argon will be subjected to future steel quality demands. As production of high purity Argon is an high energy

intensive and cost effective process so it may be deemed as part of revamping package

of Pakistan Steel.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.